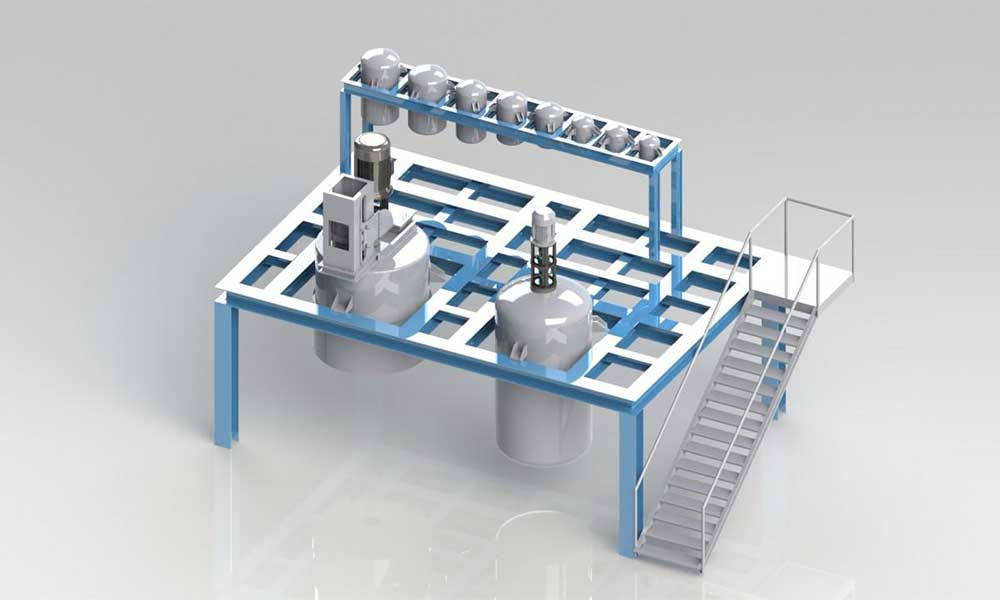

Atommek specializes in designing and building highly efficient water- and solvent-based paint production plants. Our facilities provide eco-friendly, scalable, and technologically advanced solutions to meet the growing demand for sustainable paint production.

Water-Based Paint Production Plants

Water-based paints, also known as latex or acrylic paints, use water as a solvent instead of traditional organic solvents. These paints are environmentally friendly, emit fewer VOCs, and are safer for workers and consumers.

Raw Material Preparation

- Pigments: Mixed with water and additives to form a uniform slurry. Pigment choice determines the paint’s color and properties.

- Binders: Polymers or resins bind pigment particles and ensure adhesion to surfaces.

- Mixing & Dispersion: High-speed dispersers break down pigment agglomerates for a homogenous mixture.

- Grinding: Ensures the desired particle size for better color intensity and paint quality.

- Formulation: Additives such as thickeners, surfactants, stabilizers, and defoamers are included for consistency and stability.

- Testing & Quality Control: Paint is tested for color, viscosity, durability, and other specifications.

- Filling & Packaging: Finished paint is safely packaged for distribution.

Advantages of Water-Based Paint

- Dries faster and more flexible than oil-based paints

- Safer for health and the environment

- Easy to clean and maintain

- Suitable for a wide range of applications, including wood, walls, and industrial surfaces

Solvent-Based Paints

Solvent-based paints use organic solvents like mineral spirits. They are more durable and often preferred for high-friction surfaces, such as floors. However, they emit toxic fumes, are flammable, and require special disposal methods, making them less environmentally friendly than water-based paints.

Atommek Services for Paint Production Plants

- Plant Design: Flexible and scalable to your production needs

- Equipment Selection & Procurement: Optimized for efficiency and quality

- Installation & Commissioning: On-time delivery, within budget

- Automation Systems: Streamlined operations for consistent results

- Quality Control: Continuous monitoring and improvement

- Project Management: Comprehensive support from planning to completion

We provide comprehensive solutions for every type of paint, from eco-friendly water-based formulations to the highly durable solvent-based options required for demanding industrial applications.

FAQs: Water-Based vs Solvent-Based Paint

What’s the difference between water-based and solvent-based paint?

Water-based paint uses water as a solvent, dries quickly, emits fewer VOCs, and is flexible. Solvent-based paint uses organic solvents, is more durable, but emits toxic fumes and is flammable.

Can I paint solvent-based over water-based paint?

Yes, but the water-based layer must be fully cured. Sanding and applying a primer ensures proper adhesion.

How to remove water-based paint from plants?

Use water and mild detergent for small-scale removal. Industrial applications use automated washing techniques or water-based cleaning solutions.

Why should you avoid solvent-based paint?

Solvent-based paints release VOCs, are toxic, flammable, and harmful to the environment. Water-based paints are safer and more sustainable.

What are the main types of water-based paint?

- Acrylic: Durable, fast-drying, suitable for walls and exteriors

- Vinyl: Cost-effective, good for interior walls

- PVA (Polyvinyl Acetate): Excellent adhesion and smooth finish for interiors

Why Choose Atommek

- Expertise: In-depth knowledge of paint production processes

- Sustainability: Environmentally friendly and energy-efficient solutions

- Customer-Focused: Tailored solutions and support at every project stage

- Advanced Technologies: Raw material preparation systems, polymerization reactors, dispersion systems, and automated filling & packaging

Ready to Begin?

Take the first step toward a more efficient and sustainable paint manufacturing facility.

- ✅ Request a Quote: Get a customized proposal for your paint production plant.

- ✅ Schedule a Consultation: Speak with our engineering experts to discuss your project needs and explore a tailored solution.

- ✅ See Our Projects: Explore our project page to see our successful paint plant installations worldwide.

Paint Plant Equipment

(Direct link to our equipment page)

Upgrades for Existing Paint Plants

At Atommek, we help clients upgrade existing water- and solvent-based paint plants with high-quality equipment from trusted suppliers. Our modular upgrades improve efficiency, quality, and sustainability without a full plant overhaul.

Upgrade Options

- Raw Material Preparation: Dispersers, grinders, dosing systems for uniform mixing.

- Polymerization & Reactors: Advanced, energy-efficient reactors for precise control.

- Dispersion & Mixing: Agitators and automated mixers for consistent pigment distribution.

- Filling & Packaging: Automated systems suitable for water- and solvent-based paints.

- Automation & Quality Control: PLC/SCADA integration and testing equipment for reliable results.

Benefits

Increased efficiency, better product quality, safer operations, and lower environmental impact.