Advanced Varnish Production Plants for Industrial Manufacturers

At Atommek, we specialize in designing and building complete varnish production plants tailored for the global coating industry. Varnish is a key element in surface finishing, providing a durable, transparent, and protective layer that enhances gloss and ensures long-lasting protection for wood, automotive, and industrial applications.

With our advanced engineering and international expertise, we deliver turnkey varnish factories equipped with the latest technologies. This ensures your investment is efficient, profitable, and sustainable.

Our End-to-End Project Lifecycle

We provide more than machinery—we deliver a complete project lifecycle to ensure your plant is future-proof:

- On-Site Feasibility & Measurement – Our engineers visit your site to evaluate your infrastructure and conduct precise measurements.

- Custom Formulation Support – In collaboration with specialized laboratories, we develop varnish formulations that match your market needs.

- Pilot Plant Testing – A small-scale production line is built and tested in our Gebze Technical Lab. This R&D phase, often in partnership with universities, validates your process for consistent results.

- Full-Scale Plant Delivery – Once validated, we design, build, and install your complete varnish production facility.

Process & Equipment Solutions

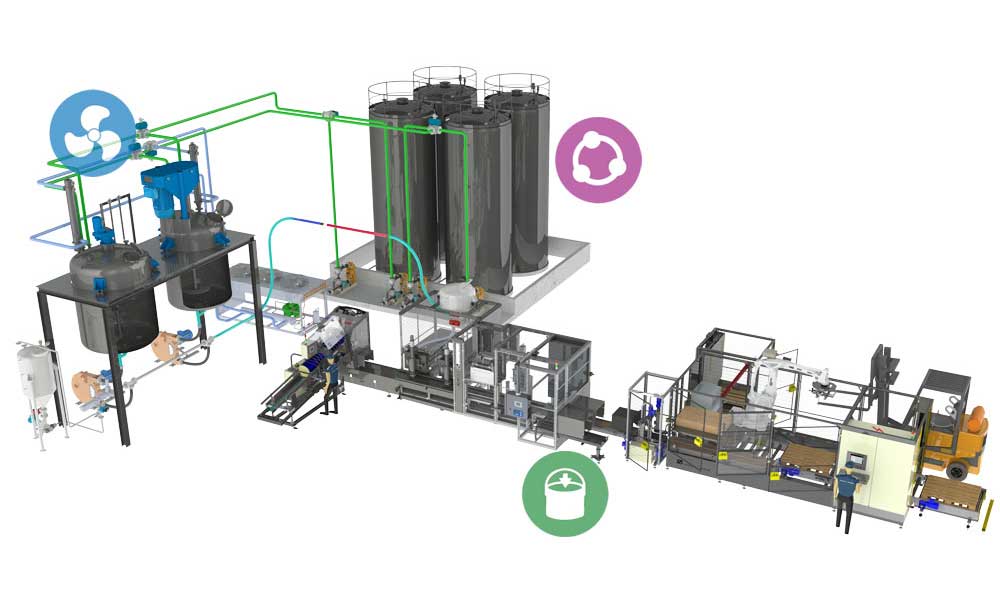

Whether you want a complete turnkey plant or only wish to upgrade specific parts of your existing facility, we offer flexible solutions. You can select individual machines or systems—such as mixers for precise raw material blending, filling machines for accurate packaging, and tanks, pumps, and piping for optimized processing.

Mixing

High-performance mixers for raw material preparation ensure homogeneous blends for transparent or pigmented varnishes.

Filling

Flexible filling machines for small, medium, and large container formats—semi-automatic or fully automated.

Processing

We provide piping, tanks, pumps, and reactors optimized for chemical reactions, dispersion, filtration, and solvent handling.

Upgrade or Customize: Our equipment can be integrated into existing plants, or customized to meet specific production requirements.

Key Features of Atommek Varnish Plants

- Raw Material Preparation Systems: Uniform input mixing for quality consistency.

- Advanced Reactors: Optimized chemical control for superior varnish quality.

- Dispersion Systems: Even pigment and additive distribution for a flawless finish.

- Filtration & Packaging: Ready-to-use high-quality varnish output.

- Automation & Control: Real-time monitoring for precision, efficiency, and safety.

Why Partner with Atommek?

- End-to-End Solutions: From design to commissioning, a single point of contact.

- Global Expertise: Successful projects across Europe, Turkey, China, Africa, and the Middle East.

- Technical Excellence: In-house R&D and pilot testing validate every process.

- ROI Focused: Plants engineered for efficiency and long-term profitability.

- Sustainable Engineering: Eco-conscious solutions reduce waste and emissions.

Applications of Varnish

Our plants produce varnishes for diverse industries:

- Wood Finishing: Furniture, flooring, and decorative panels.

- Automotive Coatings: Protective and aesthetic finishes.

- Construction & Architecture: Durable surface coatings.

- Industrial Machinery: Corrosion resistance and equipment protection.

- Specialty Finishes: Decorative and functional applications.

References & Our Clients

We have delivered successful projects worldwide. Our solutions are trusted by leading varnish and coating manufacturers.

(Here you can insert logos)

Frequently Asked Questions (FAQ)

What is a varnish plant?

A specialized facility with reactors, mixers, dispersion systems, and packaging lines for industrial and decorative varnishes. Atommek designs and builds turnkey plants.

What is the varnish production process?

Mixing raw materials, chemical reactions, dispersion, filtration, and packaging—all meeting international quality and safety standards.