At Atommek, we design and deliver turnkey phenol production plants for the global chemical industry. Our phenol facilities are engineered for maximum yield, safety, and sustainability, ensuring long-term efficiency and compliance with international standards.

Why Choose Atommek Phenol Facilities?

- Turnkey Solutions – From design and engineering to commissioning and after-sales service.

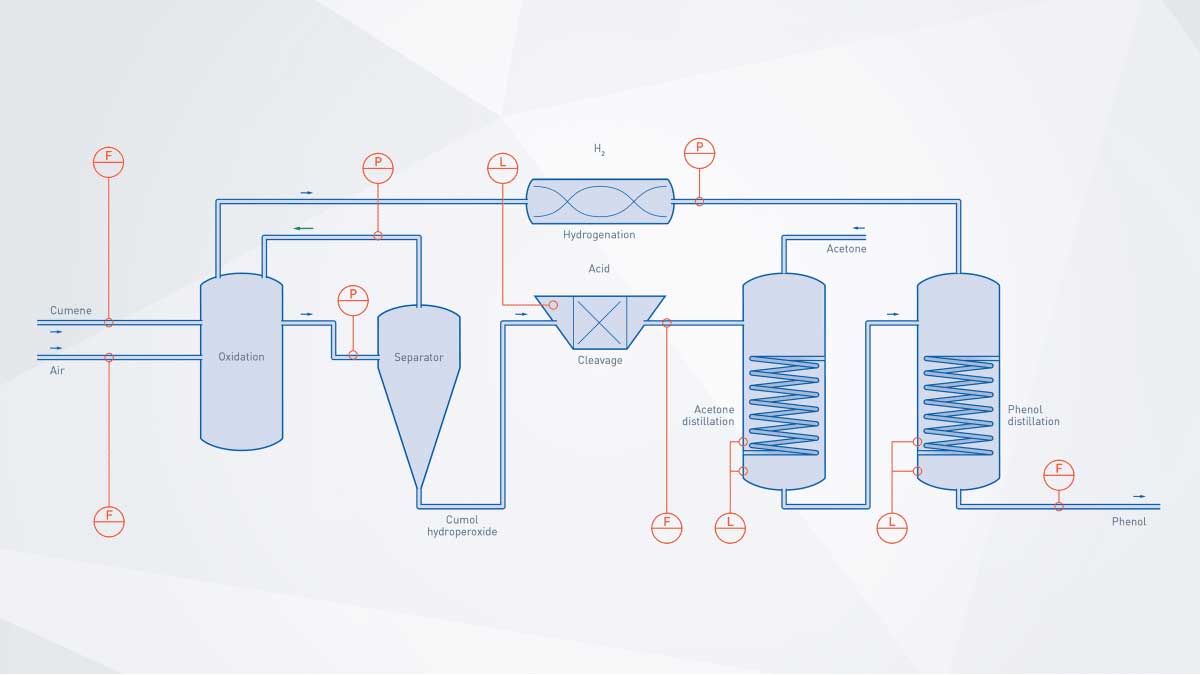

- Optimized Technology – Advanced cumene-to-phenol process with integrated acetone recovery.

- Safety & Compliance – Explosion-proof equipment, emission control, and international safety standards.

- Custom Capacities – Tailor-made designs for small, medium, and large-scale producers.

- Automation Systems – Digital DCS/SCADA solutions for real-time monitoring and control.

Applications of Phenol

Phenol is a key raw material used in:

- Bisphenol-A for polycarbonate plastics

- Caprolactam for nylon fibers

- Phenolic resins for adhesives and coatings

- Pharmaceuticals and specialty chemicals

Atommek Expertise in Phenol Plants

With extensive experience in chemical plant engineering, Atommek is a trusted phenol plant manufacturer. We provide reliable, efficient, and sustainable solutions with complete lifecycle support — including commissioning, training, spare parts, and long-term service.

Frequently Asked Questions (FAQ)

What is a phenol facility?

A plant designed to produce phenol (C₆H₅OH), often together with acetone, using the cumene process.

Can Atommek customize phenol plants?

Yes, our team provides tailor-made solutions for different capacities and integration needs.

Does Atommek offer after-sales support?

Absolutely. We provide full technical service, spare parts, and operator training.