What is a petrochemical plant?

A petrochemical plant is an industrial facility where oil, petroleum, and natural gas are processed into essential chemical products. These plants produce fuels, plastics, resins, fertilizers, and intermediates for consumer goods and other industries.

At Atommek, we specialize in turnkey petrochemical plant manufacturing, covering everything from design and engineering to equipment manufacturing, plant installation, and commissioning. Our goal is to help investors and industrial companies launch, upgrade, or expand petrochemical factories efficiently, safely, and sustainably.

Petrochemical plants vs. refineries

What is the difference between a refinery and a petrochemical plant?

- Refineries primarily process crude oil to produce fuels, MGO fuel, gasoline, diesel, fuel oil, and petroleum products.

- Petrochemical plants focus on chemical production, transforming hydrocarbons into plastics, resins, polymers, solvents, and other industrial materials.

Both are key components of the chemical industry, but petrochemical plants are specifically designed for manufacturing chemical derivatives, while refineries produce fuel-based products.

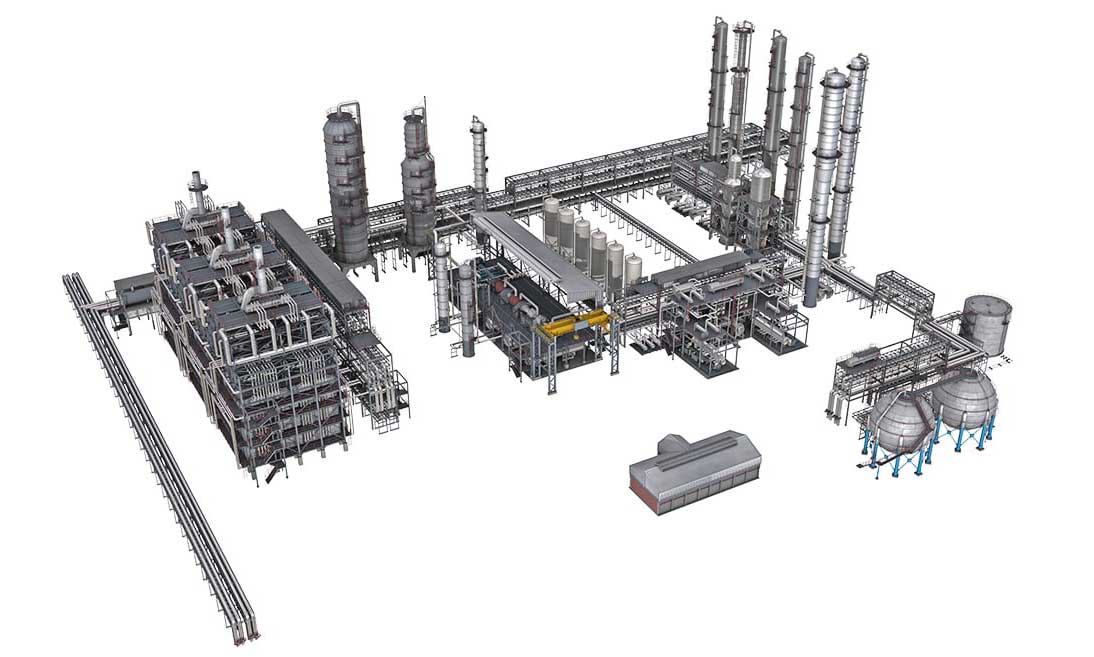

Components of a petrochemical plant

What are the components of a petrochemical plant? Typical components include:

- Reactors & blenders: For chemical reactions and processing of petroleum products.

- Storage tanks & silos: For crude oil, naphtha, MGO fuel, and chemical intermediates.

- Heating & cooling systems: For precise process control.

- Piping & instrumentation: Ensures safe material transfer within the plant.

- Automation & control systems: PLCs, CIP systems, and monitoring for process efficiency.

- Quality control laboratories: To ensure product standards and compliance.

Petrochemical plant process & manufacturing

The petrochemical plant process involves several stages:

- Raw material processing: Crude oil, petroleum, and natural gas are prepared for chemical reactions.

- Chemical reactions: Hydrocarbons are transformed into useful products using reactors, mixers, and specialized equipment.

- Separation & purification: Products such as naphtha, LPG, and resins are separated and refined.

- Product storage & handling: Safe storage in tanks and silos ensures quality and regulatory compliance.

- Packaging & distribution: Finished products are delivered to other industries or end-users.

Common petrochemical products

- Plastics: Polyethylene (PE), Polyvinyl Chloride (PVC), Polystyrene (PS)

- Chemical intermediates: Polymers, solvents, resins

- Fuels & oils: Diesel, gasoline, fuel oil, MGO fuel, asphalt, paraffin, tar

- Agricultural & consumer chemicals: Fertilizers, pesticides, cosmetics

Petrochemical plant services by Atommek

- Plant design & engineering: Custom layouts for factory efficiency, safety, and compliance.

- Plant manufacturing & equipment procurement: Turnkey reactors, blenders, storage tanks, silos, and automation systems.

- Plant installation & construction: Complete assembly, instrumentation, insulation, wiring, testing, and commissioning.

- Automation & control systems: Advanced PLC, CIP, and monitoring systems for process optimization.

- Project management & consultancy: Budget control, workflow optimization, regulatory compliance, and timeline management.

- Sustainability & compliance: Environmentally responsible designs meeting global standards.

Petrochemical companies in Turkey & industrial investors

For investors exploring petrochemical opportunities in Turkey, Atommek delivers solutions for establishing new factories, expanding existing plants, and optimizing petrochemical processes. Turkey’s industrial sector provides a strategic market for chemical and petrochemical plant projects.

Why choose Atommek for petrochemical plants?

- Engineering expertise: Decades of experience in complex petrochemical plant manufacturing.

- Turnkey solutions: Complete support from design to commissioning.

- Custom equipment & processes: Tailored to your plant project and product portfolio.

- Global standards: Safety, quality, and environmental compliance.

- Investor-focused solutions: Guidance for new facilities, plant upgrades, and process optimization.

Partner with Atommek

Whether you are a global investor or an industrial company, Atommek provides scalable, high-performance petrochemical plant solutions.

Contact us today to plan your petrochemical plant project, receive tailored consultation, and transform your investment into a fully operational factory.