What is plant antifreeze?

An antifreeze plant is an industrial facility producing antifreeze to lower the freezing point in automotive engines, water cooling systems, and industrial applications. Atommek specializes in turnkey antifreeze plant manufacturing, guiding investors and industrial companies from infrastructure evaluation to full plant commissioning.

Before starting, we conduct a site visit to take precise measurements of your infrastructure to ensure smooth project execution. Explore our Projects page to see our successful installations worldwide.

Whether you want to buy production machines only, or build a full antifreeze factory, Atommek provides solutions tailored to your goals.

How is antifreeze made?

Antifreeze production uses raw materials such as ethylene glycol or propylene glycol, processed in several stages:

- Raw material preparation – ensuring quality and consistency.

- Mixing – using specialized mixers for precise formulation.

- Filtration – removing impurities to maintain product quality.

- Storage – proper containment in tanks ready for distribution.

Learn more about our Antifreeze Production Facility Services to understand the equipment and machinery we offer.

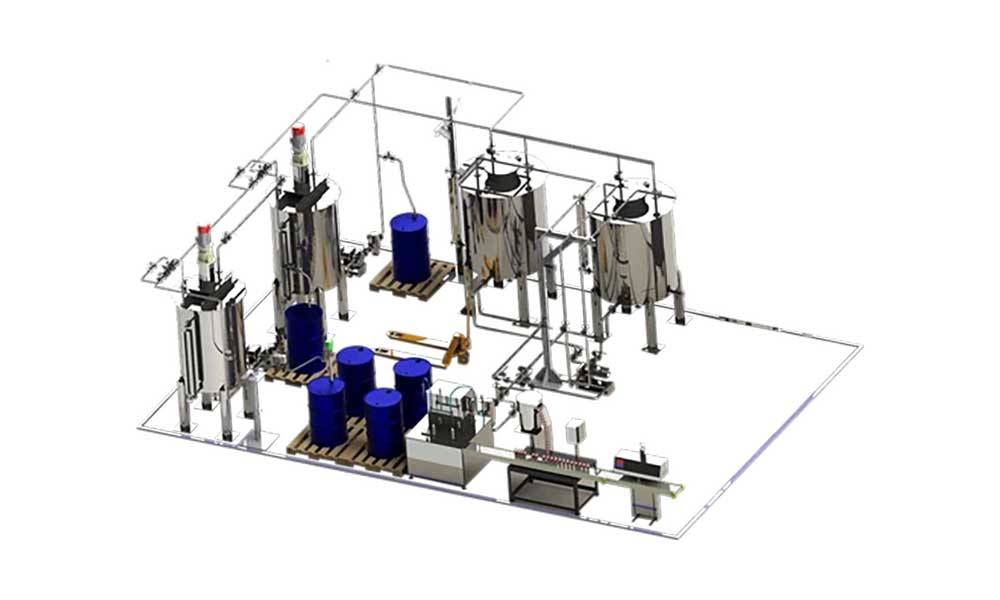

Antifreeze plant installation & equipment

Our turnkey antifreeze plant services include:

- Plant design & engineering – custom layouts ensuring safety, efficiency, and compliance.

- Equipment selection & procurement – mixers, storage tanks, filling machines, and cooling systems. See our Machines & Factory Equipment page for details.

- Installation & commissioning – full on-site assembly, instrumentation, insulation, wiring, testing, and commissioning.

- Automation & process control – advanced PLC and CIP systems for precise production.

- Project management – complete oversight to keep your antifreeze plant on schedule and budget.

Before launching full-scale production, we implement a universal R&D plant, allowing you to test formulations and optimize processes. Check our Universal Plant Services page to learn more.

Antifreeze plant cost & consultancy

The cost of an antifreeze plant depends on capacity, technological requirements, and raw materials. Atommek provides budget-friendly solutions and ensures cost efficiency.

Our consultancy services cover:

- Planning and design stages

- Equipment selection

- Construction and commissioning

- Ongoing maintenance and optimization

Learn more about our Consultancy Services to start your antifreeze plant project with expert guidance.

Safety & industry insights

- Are any plant species able to make antifreeze? Some plants produce natural antifreeze proteins, but industrial antifreeze is chemically formulated.

- Is antifreeze safe for plants? Industrial antifreeze is toxic and should never be used in agriculture.

We ensure all antifreeze plant processes comply with international safety and environmental standards.

Why choose Atommek for antifreeze plants?

- Certified & experienced – over 20 years of experience in antifreeze plant manufacturing.

- Turnkey solutions – from concept, universal plant testing, to full production factory setup.

- High-quality equipment – mixers, tanks, filling systems, and cooling units.

- Project management – timely delivery, budget control, and smooth operations.

- R&D & universal plants – test your production processes before scaling up.

- Global support – serving industrial investors and companies worldwide.

Partner with Atommek

Whether you are an investor establishing a new antifreeze factory, upgrading your facility, or just want to purchase machines, Atommek provides complete solutions for efficient, safe, and high-quality antifreeze production.

Contact us today for a consultation and begin your antifreeze plant project with Atommek.