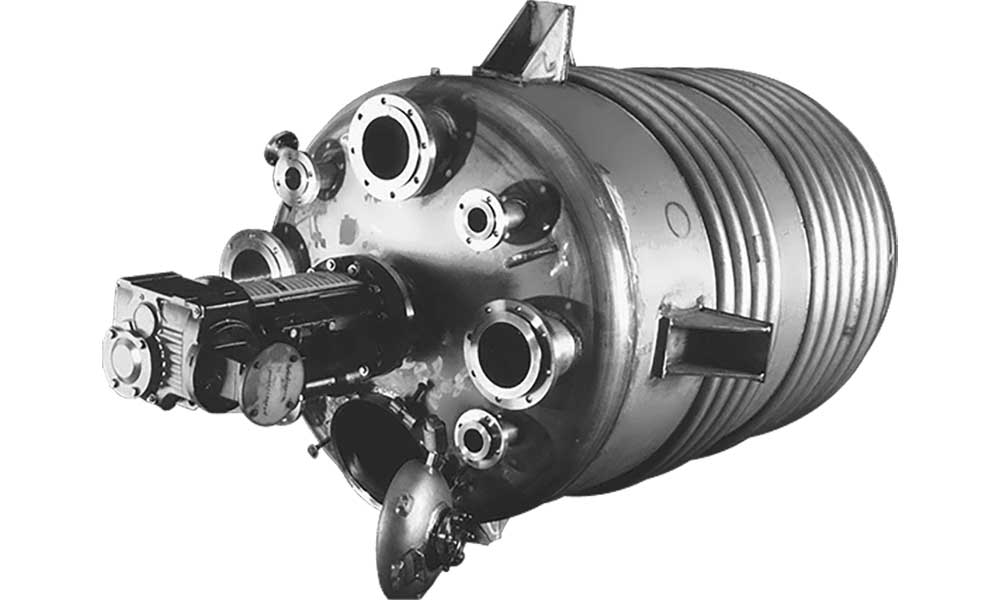

Industrial Stainless Steel Reactor & Mixing Tank

Precision Engineering for Global Chemical Industries

From chemical manufacturing and petrochemicals to pharmaceuticals, polymers, food, and fuel industries, Atommek’s stainless steel reactor solutions are trusted worldwide to optimize reaction efficiency, product yield, and process reliability.

Working Principle

Our stainless steel reactors operate by mixing reactants in a corrosion-resistant vessel using an internal agitator. Precise temperature and pressure control is maintained via jackets or coils, ensuring optimal reaction conditions. After the reaction, the product is safely discharged, and the reactor is ready for quick cleaning and the next batch.

Why Choose Atommek?

- Custom Design & Engineering – Tailored solutions for batch, continuous, and flow processes.

- Durable Materials – Built with premium stainless steel for long service life in harsh conditions.

- Precise Temperature & Mixing Control – Advanced jacketed and coil systems ensure uniform heating/cooling.

- Advanced Agitation Systems – Anchor, paddle, turbine, propeller, helical coil, and magnetic agitators for optimal mixing.

- Industry Compliance – Certified to ASME, PED, CE, AD2000, ATEX/EXPROOF, ensuring global safety standards.

- Scalable Solutions – From pilot reactors to large-scale industrial reactors, we cover all capacities.

Technical Specifications

| Feature | Details |

|---|---|

| Design | Custom-engineered for process-specific requirements |

| Materials | ST-37 Carbon Steel, AISI 304, 304L, 316, 316L, 316Ti Stainless Steel |

| Safety Standards | ATEX/EXPROOF, PED, CE, AD2000, ASME |

| Control Systems | PLC panels, inverter-driven mixers, precision weighing |

| Thermal Management | Jacketed or half-pipe serpentine coils for efficient heat transfer |

| Mixing Technology | High-performance mixer blades, foam breakers, agitator options |

| Capacity Range | Custom fabrication: 500L to 30,000L (30 Tons) |

| Certifications | PED, CE, AD2000, ASME |

Areas of Application

- Chemical Manufacturing – hydrogenation, oxidation, synthesis, specialty chemicals

- Pharmaceutical Industry – sterile environments, fermentation, high-purity processes

- Food & Beverage – temperature-sensitive formulations, batch/continuous cooking

- Polymer & Plastics – polyester, polyurethane, advanced polymers

- Petrochemicals & Fuels – biodiesel, hydrocarbon processing, catalytic reactions

Advantages of Atommek Reactors

- Continuous Operation – Enables uninterrupted production

- Corrosion Resistance – Designed for aggressive chemicals

- High Yield & Efficiency – Optimized for maximum conversion rates

- Versatility – Adaptable to batch, stirred, and continuous processes

- Low Maintenance – Built for durability with minimal downtime