Continuous Stirred Tank Reactors (CSTRs)

Efficient, Scalable & Uniform Chemical

Overview

A Continuous Stirred Tank Reactor (CSTR) is a vessel where reactants are continuously fed, thoroughly mixed, and products are simultaneously withdrawn. This ensures steady-state conditions, uniform product quality, and high process control.

CSTRs are widely used in chemical synthesis, bioprocessing, fermentation, wastewater treatment, and food processing. Their reliable mixing and heat transfer make them ideal for homogeneous liquid-phase reactions. For slow or complex reactions, multiple CSTRs can be linked in cascade to optimize conversion and throughput.

General Information & Design

CSTRs consist of:

- Reactor Tank (stainless steel, jacketed for heating/cooling)

- Stirring System (impellers, turbines, or pitched-blade agitators)

- Feed & Exit Lines (continuous inlet/outlet flow)

- Control & Monitoring (temperature, pressure, pH, PAT integration)

👉 Unlike Batch Reactors, CSTRs run continuously, delivering higher productivity, stable conditions, and improved temperature control.

Technical Specifications

| Feature | Specification |

| Material Options | Stainless Steel AISI 304 / 316 / 316L |

| Capacity | 50 L – 50,000 L |

| Operating Pressure | -1 to +10 bar (customizable) |

| Temperature Range | up to 300 °C |

| Mixing Systems | Anchor, Turbine, Propeller, Customized |

| Heating/Cooling | Jacketed, Limpet Coil, Half-Pipe Coil |

| Flow Operation | Continuous feed and discharge |

| Automation | PLC / SCADA, PAT integration |

| Certifications | CE, ATEX, GMP, ISO 9001 |

Advantages of CSTRs

- Uniform mixing and steady-state operation

- Easy temperature & pressure control

- Scalable for industrial production

- Flexible setup: standalone or cascade

- Accessible design for cleaning and maintenance

- More cost-effective than tubular flow systems

📌 When to Use a CSTR

- Perfect for liquid-phase reactions

- Best choice for fermentation, polymerization, and wastewater treatment

- Works excellently when consistent output quality is required

- Can be linked in cascade for higher conversion

Areas of Use

- Chemical Industry: Polymerization, catalysis, fine chemicals

- Pharmaceutical Industry: API production, fermentation, crystallization

- Biotechnology: Enzyme reactions, vaccine and biohydrogen production

- Food & Beverage: Brewing, fermentation, flavor synthesis

- Environmental: Wastewater treatment, biogas generation

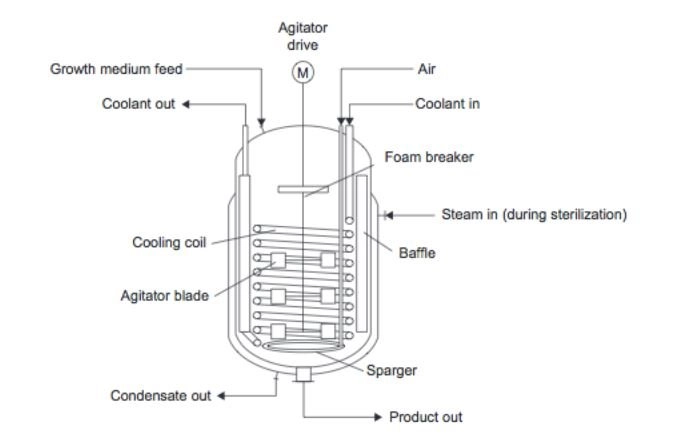

Diagram & Structure

(A diagram of CSTR with inlet/outlet flow, agitator, jacket should be shown here – downloadable as PDF datasheet).

Downloadable Content:

📄 [CSTR Technical Datasheet – PDF]

📊 [CSTR Design & Operation Diagram]

Related Products & Internal Links

- Autoclave Reactors

- Pilot Reaction

- Reactor Accessories & Spare Parts

- Stainless Steel Reactor

FAQ

What makes CSTRs different from Plug Flow Reactors (PFRs)?

CSTRs are well-mixed and deliver uniform output, while PFRs operate in sequential “plugs” with varying compositions along the tube.

Can CSTRs handle viscous or multiphase reactions?

Yes. With the right impeller and cascade setup, CSTRs are effective for viscous liquids, immiscible phases, and slurries.

What industries benefit most from CSTRs?

Chemical, pharmaceutical, biotech, food & beverage, and environmental (wastewater, biogas).