AtomMek Viscous Paste Mixers: Precision Mixing for High-Viscosity Applications

Optimize Your Production with AtomMek’s Advanced Mixing Solutions

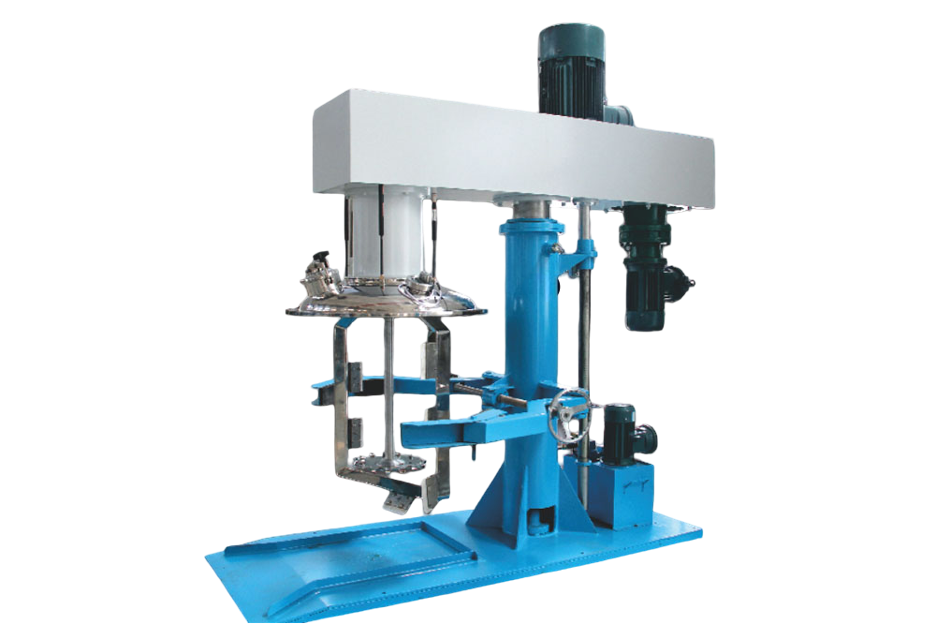

AtomMek’s Viscous Paste Mixers are engineered to deliver exceptional mixing performance for high-viscosity materials. Designed to meet the rigorous demands of industries such as adhesives, sealants, coatings, and cosmetics, our mixers ensure uniform consistency, reduced processing times, and enhanced product quality.

Key Features & Benefits

Dual Agitator System

Combines a scraper agitator with a high-speed disperser, facilitating rapid and uniform mixing even for materials with viscosities up to 100,000 cps.

Teflon Scrapers

Continuously clean the container walls, preventing material buildup and ensuring efficient mixing without residue.

Customizable Agitators

Options include frame type, half-frame type, and various dispersing discs (double disc, single disc, Niemann disc) to suit different formulations.

Vacuum Design

Available for applications requiring deaeration and prevention of air entrapment.

Temperature Control

Integrated systems for monitoring and maintaining optimal processing temperatures.

Automation Options

Semi and fully automatic PLC controls with recipe management for consistent batch production.

Applications

AtomMek’s Viscous Paste Mixers are versatile solutions for a range of high-viscosity products:

- Adhesives & Sealants: Ensures homogeneous mixing for consistent bonding properties.

- Printing Inks: Achieves uniform dispersion of pigments for vibrant and stable inks.

- Wall Putty & Plasters: Provides smooth and lump-free mixtures for superior application.

- Paints & Coatings: Delivers consistent color and texture across batches.

- Cosmetic Products: Ideal for creams, lotions, and other high-viscosity formulations requiring precise emulsification.

Technical Specifications: Explore Our Range

Model | Mixer Motor (kW) | Mixer Speed (rpm) | Dissolver Motor (kW) | Dissolver Speed (rpm) | Capacity (L) |

MC150 | 4 | 40 | 11 | 1500 | 150 |

MC300 | 5.5 | 25 | 15 | 1500 | 300 |

MC500 | 7.5 | 25 | 22 | 1500 | 500 |

MC1000 | 11 | 25 | 37 | 1500 | 1000 |

MC1500 | 15 | 25 | 55 | 1500 | 1500 |

Optional Features

- ATEX Certification: Compliance with Ex II 2 G c IIB T3 standards for explosive environments.

- Stainless Steel Mixing Containers: For enhanced durability and hygiene.

- Double Dispersing Disc: Improves mixing efficiency for complex formulations.

- Platform Balance: Facilitates accurate measurement and control.

- Extruder/Screw Pump: Enables efficient product discharge.

Why Choose AtomMek?

With over 30 years of expertise in processing solutions, AtomMek is a trusted partner for industries worldwide. Our commitment to innovation, quality, and customer satisfaction ensures that our mixing equipment meets the highest standards of performance and reliability.