Efficient Thermal Solutions for Chemical, Food & Pharma Industries

At AtomMek, we provide heat exchanger solutions designed for your industrial needs, delivering high energy efficiency, long service life, and easy maintenance. Using premium materials and innovative engineering, our heat exchangers help optimize processes while reducing energy consumption.

What is a Heat Exchanger?

A heat exchanger is a device that transfers heat between two or more fluids without mixing them. These systems are essential for temperature control and process efficiency in chemical, pharmaceutical, and food processing.

Fields of Use:

- Chemical & Petrochemical: heating, cooling, condensation, evaporation

- Food & Beverage: pasteurization, cooling, fermentation

- Pharmaceutical & Biotech: sterile heating/cooling, fermentation

- Energy & Utilities: energy recovery and process optimization

Our Tanks Serve Key Industries

- Chemical Manufacturing: Safe storage for acids, polymers, and other materials.

- Oil & Gas: Tanks for fuels, lubricants, and petrochemicals.

- Food & Beverage: Sanitary tanks that meet food-grade standards.

- Pharmaceuticals & Biotech: High-purity storage with GMP options.

- Water Treatment: Storage for raw, treated, and effluent water.

- Power & Energy: Tanks for fuel, deionized water, and thermal storage.

Heat Exchanger Types in Our Portfolio

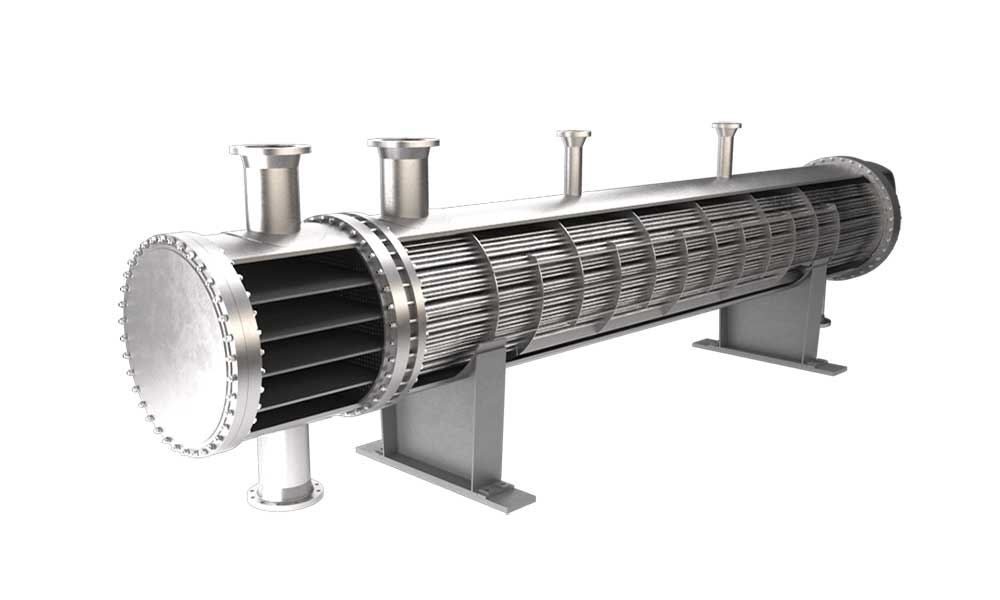

1. Fixed Tube / Shell & Tube (Tubular) Heat Exchangers

- Ideal for high-pressure and high-temperature chemical processes

- Efficient energy transfer for viscous or corrosive fluids

- Built with stainless steel and special alloys

- Applications: reactors, condensers, distillation columns

➡️ Learn more: Shell & Tube Heat Exchangers

2. Double Pipe Heat Exchangers

- Suitable for smaller capacities and simple installations

- Easy to maintain and clean

- Applications: chemical cooling, heating, and pharma solutions

- Can be custom-designed for flow rate and temperature requirements

➡️ Learn more: Double Pipe Heat Exchangers

3️. Crossflow Heat Exchangers

- Allows efficient heat transfer when fluids flow perpendicular to each other

- Compact and energy-efficient design

- Applications: chemical, food, and pharmaceutical processes with medium flow rates

➡️ Learn more: Crossflow Heat Exchangers

4. Plate Heat Exchangers

- Ideal for hygienic applications in food & pharma

- Available in gasketed, welded, and brazed designs

- Offers high heat transfer with minimal footprint

- Applications: pasteurization, cooling, CIP systems, fermentation

➡️ Learn more: Plate Heat Exchangers

Advantages of AtomMek Heat Exchangers

✅ Energy Efficiency: High-performance heat transfer

✅ Long Life Design: Corrosion-resistant materials and advanced production techniques

✅ Flexible & Modular: Solutions suitable for varying capacities

✅ Easy Maintenance: Designed for uninterrupted operation

✅ Custom Design & Types: Fixed tube, double pipe, crossflow, and plate exchangers

Sectors of Use

- Chemicals & Petrochemicals → high-temperature and corrosive processes

- Food & Beverage → hygienic cooling and heating

- Pharmaceuticals & Biotech → sterile and clean media processing

- Energy & Utilities → thermal management and energy recovery

Get Started

Provide your project details for a fast and accurate proposal:

- Medium: What substance will be stored?

- Capacity: Required volume?

- Conditions: Operating temperature and pressure?

- Standards: Any specific compliance needed?

- Location: Where will the tank be installed?

CTA: Request a Datasheet Template to make it easy to provide the necessary info.

FAQ

Q1: Which heat exchanger type is best for chemical processes?

A: Fixed tube (shell & tube) and crossflow heat exchangers are most common for chemical industries due to their efficiency and ability to handle viscous or corrosive fluids.

Q2: Can AtomMek heat exchangers be used in pharma and food?

A: Yes. Plate and double pipe exchangers are ideal for hygienic applications requiring easy cleaning and sterilization.

Q3: How do I select the right heat exchanger?

A: Selection depends on fluid properties, flow rate, temperature, and space constraints. AtomMek provides customized design consultation.

Q4: Are spare parts and maintenance available?

A: Yes, AtomMek provides spare parts, maintenance support, and service for long-term reliability.

Q5: Can AtomMek provide design formulas or technical specifications?

A: Yes, detailed design calculations, thermal formulas, and datasheets are available upon request.

Why Choose AtomMek?

✅ Expert design formulas for efficient heat transfer

✅ High-quality stainless steel & alloy materials

✅ Reliable manufacturing and after-sales support

✅ Proven track record in chemical, food, and pharmaceutical sectors

Certifications & Quality Assurance

- ISO 9001

- CE Certification

- SGS Testing Available