What is the single most common and most expensive mistake in industrial agitation?

It isn’t about motor speed or tank size. It’s about fundamentally misunderstanding viscosity.

In process engineering, applying the wrong agitation method to a high-viscosity product does more than just mix poorly. It wastes an enormous amount of energy, creates damaging hotspots, and can lead to complete batch failure.

Understanding the critical difference between low-viscosity turbulent flow and high-viscosity laminar flow is the first step to optimizing your process, reducing energy costs, and ensuring perfect product homogeneity.

The Core Conflict: Turbulent vs. Laminar Flow

The “physics” of industrial agitation changes completely as a product gets thicker.

1. Turbulent Flow (Low Viscosity) This is what most people picture as “mixing.” Think of dissolving sugar in water. It’s a chaotic, high-motion, low-drag environment. The goal is to create high shear and rapid currents to blend components quickly. A low-viscosity fluid (like water or solvents) has a high Reynolds number, indicating this turbulent state.

2. Laminar Flow (High Viscosity) This is what happens when you mix honey, resin, or a thick cream. The fluid moves in smooth, parallel layers (“laminae”). There is no turbulence. The product has high internal friction (high drag), and it resists being mixed. The Reynolds number is very low.

The problem? Using a “turbulent flow” agitator in a “laminar flow” product is a recipe for disaster.

The “Vortex” Problem: When High-Speed Fails in High-Viscosity

Let’s say you have a large tank of thick polymer resin. You install a standard, high-speed marine-type propeller, expecting it to churn the entire batch.

Instead, this is what happens:

- The high-speed impeller “drills a hole” (a vortex) in the center of the tank.

- The product directly around the impeller is over-sheared and heated, which can degrade or “burn” the product.

- The valuable product at the tank walls does not move at all.

- You get zero top-to-bottom turnover, resulting in a completely non-homogeneous batch.

You are effectively paying to heat a small column of liquid while 80% of your product remains stagnant. This is where high-torque, low-speed mixing becomes essential.

Low Viscosity Solutions in Industrial Agitation

When your viscosity is low, your goal is Axial Flow—pushing the liquid from the top to the bottom of the tank to create a strong, full-tank circulation.

- Pitched-Blade Turbines: These are the workhorses of low-to-medium viscosity mixing. The angled blades create a powerful downward (or upward) flow, perfect for blending liquids or keeping solids in suspension.

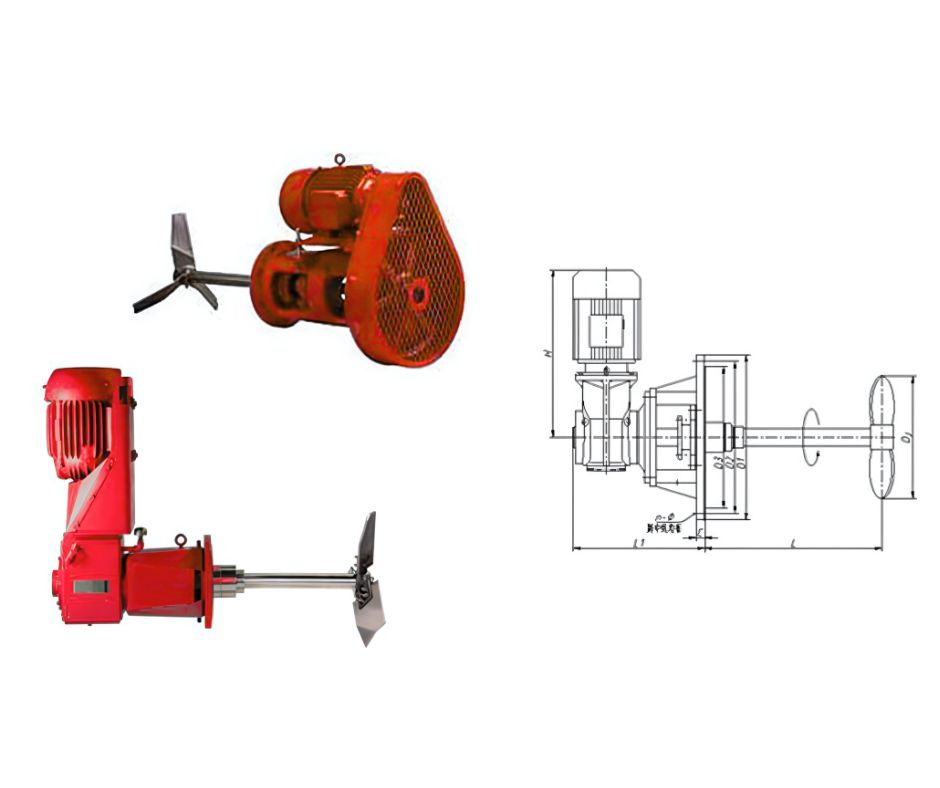

- Marine-Type Propellers: Highly efficient at creating axial flow at high speeds. They are the ideal choice for simple blending applications in water-like liquids.

Pro-Tip: In low-viscosity, baffles (plates installed on the tank wall) are crucial. They prevent the entire batch from spinning in a circle and help break the vortex, forcing the liquid to mix properly.

High Viscosity Solutions in Industrial Agitation

When viscosity is high, you must abandon speed and embrace Torque. The goal is Radial Flow (pushing from the center to the walls) and ensuring the entire batch is in motion.

These agitators are large, turn slowly, and have a high “wetted surface area” to physically move the product.

- Anchor Agitators: These are the classic solution. The agitator is shaped like the tank (an “anchor”) and sweeps the walls at a low speed.

- Benefit: It physically scrapes the product off the walls, which is critical for heat transfer (preventing burn-on) and ensuring the product at the edges is mixed into the batch.

- Helical Ribbon Agitators: This is the ultimate solution for very thick, pasty products. It consists of two or more “ribbons” winding around a central shaft.

- Benefit: A helical ribbon creates simultaneous mixing actions. The outer ribbon scrapes the wall and lifts the product, while the inner ribbon (often reversed) pushes product down the center. It provides unparalleled top-to-bottom and radial mixing for the most difficult, non-flowing products.

Conclusion: Stop Wasting Energy. Start Mixing Smarter.

High performance in industrial agitation isn’t about mixing faster; it’s about mixing smarter. The right agitator may look less dramatic turning slowly but powerfully but it delivers a perfectly homogeneous product every time.

Choosing the right impeller for your viscosity guarantees product consistency, shortens your batch times, and, most importantly, provides massive reductions in energy consumption.

Is your current process creating a vortex? Are your energy bills too high, or are your batch times too long? Your agitation system is likely the problem.

Contact the engineering experts at Atommek today for a full audit of your agitation system. We design and build solutions engineered for your success.