AtomMek Ribbon Blenders – Efficient Bulk Blending for Powders and Granules

Achieve Consistent, Homogeneous Mixing at Every Batch Size

Why Choose AtomMek Ribbon Blenders?

Ribbon Blenders are ideal for dry powders, granular solids, and pasty materials. AtomMek offers robust, hygienic designs suitable for food, chemical, and pharmaceutical mixing needs.

Gentle and Effective Mixing

Double helix agitator ensures thorough blending with minimal shear – protecting particle integrity.

Easy Cleaning and Maintenance

Polished interiors, quick-open covers, and CIP-ready options simplify cleaning.

Uniform Mixing at All Scales

From 50L to 10,000L batch sizes, our blenders deliver precise mixing consistency.

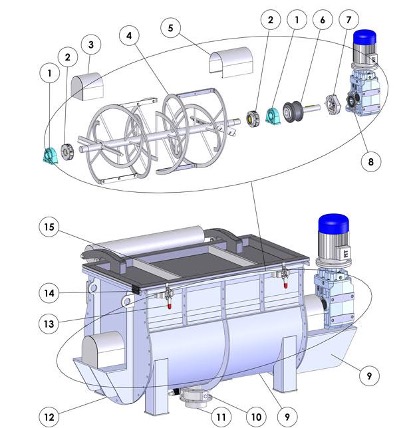

How Ribbon Blenders Work

A central shaft rotates helical ribbons in opposite directions, moving material both inward and outward, ensuring fast and even distribution.

The Process Steps

- Materials loaded via top.

- Ribbon agitator lifts and folds mix.

- Final product discharged via bottom valve.

Applications of AtomMek Ribbon Blenders

- Food powders (spices, flour, protein blends)

- Pharmaceuticals (nutraceuticals, bulk actives)

- Chemicals (fertilizers, pigments, polymers)

- Cosmetics (powdered bases, scrubs)

Construction & Customization

- Materials: SS316L / SS304 / Carbon Steel

- Finish: Mirror polish / Bead blast

- Capacity: 50 – 10,000L

- Discharge: Pneumatic valve / Manual valve

Construction & Customization

Materials: SS316L / SS304 / Carbon Steel

Finish: Mirror polish / Bead blast

Capacity: 50 – 10,000L

Discharge: Pneumatic valve / Manual valve

Technical Specifications

Model | Volume (L) | Motor (kW) | Construction Material | Mixer Type | Discharge Type |

RBM-100 | 100 | 3.0 | SS316L | Twin Ribbon | Manual Valve |

RBM-500 | 500 | 5.5 | SS316L / CS | Twin Ribbon | Pneumatic |

RBM-2000 | 2000 | 11 | SS316L | Twin Ribbon | Slide Gate |

Certifications & Quality Assurance

- ISO 9001

- CE Certification

- SGS Testing Available

Contact Information

WhatsApp: +90 545 678 72 30

Email: [email protected]